Major Uses & Application of 2000 Liter RO Plant :

- Hospitals & Laundries & Laboratories

- Swimming Pools & Beverages Industries

- Textile Industries

- Hotels & Breweries Industries

- Chemical Industries & Pharmaceutical Industries

| RO Capacity | 2000 |

| Working Pressure | 101 – 200 PSI |

| Material | FRP |

| Automation Grade | Automatic |

| RO Membrane Type | Cellulose acetate (CA) |

| Media | Activated Carbon + sand |

| Model Name/Number | TRA107 |

| Usage/Application | Water Purification |

| Brand | TRAqua |

| Minimum Order Quantity | 1 |

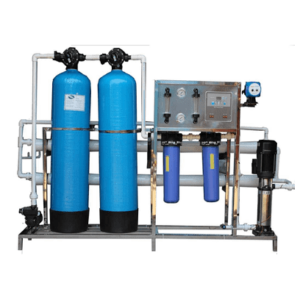

A 2000 LPH RO plant is an advanced water purification system designed to provide safe and clean drinking water by removing impurities, contaminants, and dissolved solids. Ideal for medium to large-scale applications, this system ensures high-quality water suitable for drinking, cooking, and various industrial processes.

Features of the 2000 LPH RO Plant

- High-Quality Filtration: Utilizes a multi-stage filtration process, including sediment filters, activated carbon filters, and reverse osmosis membranes, to effectively remove up to 99% of dissolved salts, contaminants, and impurities.

- High Flow Rate: Capable of producing 2000 liters of purified water per hour, making it suitable for institutions, factories, schools, hospitals, and other facilities with a high demand for clean water.

- Durable Construction: Built with high-grade stainless steel and corrosion-resistant materials to ensure long-lasting performance and reliability.

- Advanced Control System: Equipped with a user-friendly control panel for easy monitoring and operation. Features automated functions such as auto shut-off, low-pressure protection, and water level indicators.

- Energy Efficient: Designed to minimize energy consumption while maximizing water recovery rates, making it an environmentally friendly choice.

- Low Maintenance: Easy-to-replace filters and components reduce downtime and maintenance costs.

Benefits of Using a 2000 LPH RO Plant

- Consistent Water Quality: Ensures a steady supply of pure water free from harmful chemicals, heavy metals, bacteria, and viruses.

- Cost-Effective: Reduces the need for bottled water and lowers operational costs by providing a sustainable water solution.

- Versatile Applications: Suitable for a variety of uses including drinking water, food processing, pharmaceuticals, and industrial applications.

- Health Benefits: Provides clean and safe drinking water, which is essential for maintaining good health and preventing waterborne diseases.

- Environmentally Friendly: By reducing the need for bottled water, it helps in minimizing plastic waste and conserving natural resources.

Technical Specifications

- Capacity: 2000 Liters per hour

- Recovery Rate: Up to 50%

- Rejection Rate: Up to 99%

- Operating Pressure: 10 – 15 bar

- Power Supply: 220V/50Hz or 440V/50Hz (depending on model)

- Pump Type: High-pressure booster pump

- Membrane Type: Thin Film Composite (TFC)

- Frame Material: Stainless steel

Maintenance Tips

- Regular Filter Replacement: Change sediment and carbon filters every 6-12 months to maintain efficiency and water quality.

- Membrane Cleaning: Clean the RO membrane periodically based on usage and water quality to extend its lifespan.

- Check for Leaks: Regularly inspect all connections and fittings for leaks and ensure they are tightened properly.

- Monitor Pressure Levels: Keep an eye on pressure gauges and ensure the system is operating within the recommended range.

- Annual Servicing: Schedule annual maintenance with a professional technician to inspect and service the RO plant.

Frequently Asked Questions (FAQs)

- How does the RO process work?

- The RO process involves forcing water through a semi-permeable membrane that filters out impurities, contaminants, and dissolved solids, providing clean and safe drinking water.

- What are the installation requirements for a 2000 LPH RO plant?

- The installation requires adequate space, a stable power supply, a source of raw water, and proper drainage for wastewater.

- How often should the filters be replaced?

- Filters should be replaced every 6-12 months, depending on the water quality and usage.

- What is the lifespan of an RO membrane?

- An RO membrane typically lasts 2-3 years, depending on the feed water quality and maintenance practices.

- Can the system operate continuously?

- Yes, a 2000 LPH RO plant is designed for continuous operation, provided it is properly maintained and the feed water quality is within acceptable parameters.

Reviews

There are no reviews yet.